SQUARE & RECTANGULAR PANEL TANKS

- Home

- Square & Rectangular Panel Tanks

Explore Our Tank Series – GRP (Glass Reinforced Plastic), Stainless Steel (304 & 316) + Hot Dip Galvanized

Raven American Tanks provides a variety of high-quality industrial liquid storage solutions, including Glass Reinforced Plastic (GRP) tanks, Hot Dipped Galvanized steel tanks, and Stainless Steel Panel tanks.

Here, you’ll find the ideal tank system for your specific application, along with detailed information on specifications, features, and installation guidelines.

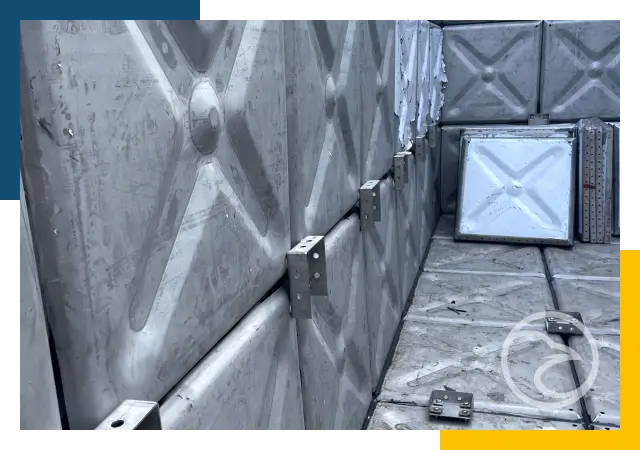

The Construction of Your Panel Tanks

Raven American Tanks’ Panel Tanks have a square design and are assembled on-site from sectional panels. These steel panels, measuring approximately 1 square meter, are bolted together with gaskets to create high-quality liquid storage units of any desired size or capacity.

Licensed professionals install plumbing, roofing, and other components, ensuring your tanks are operational and ready for filling as soon as possible.

Features

- No on-site welding required – Low-involvement bolt installations minimize disruption to your overall operations.

- Highly versatile containment – Capable of storing various content types, including potable water, fire suppression (non-potable) water, and chemicals, utilizing materials resistant to chemical reactions.

- Fully compliant with all American industry and safety standards.

- Effortless transportation and construction – Pre-fabricated for fast and streamlined assembly.

- Quick and efficient drainage.

Applications

Our panel tanks, constructed from GRP, HDG, and Stainless Steel, are incredibly versatile. Their convenient square design makes them suitable for a wide range of applications, especially those where space is a constraint.

Perfect for commercial use, including:

- Office Buildings

- Hospitals and Medical Facilities

- Laboratories and Research Facilities

- Shopping Centres and large Hospitality/Retail Precincts

- Compact Factory Sites

- Fire and Emergency Water Supply Systems

- A range of Underground and Roof-top applications

Customisable Options

While our panel tanks are offered as a comprehensive package, we can tailor them with additional features or components to suit your unique requirements.

The following design elements can be adjusted or added to your order during our planning stage:

- Ladders/Entry points – Alter the orientation or positioning of how your tank is entered.

- Signage Requirements – Instructional wording, placement and dimensional requirements.

- Roofing – Fully-covered and open-top designs.

- Ventilation – Static or Revolving Aeration.

- Chemical-resistant materials – Apply materials featuring anti-corrosive properties for hazardous liquid containment.

- Reinforced External – Panelled layers for extra strong side walls.

- Customised Piping – Plumbing configurations specially designed to fit unconventional spaces e.g. basement and rooftop locations.

- Manhole placement/Lockable Closures – Restrict access to your tanks for added safety.

- Insulation Options – Layered foam padding for protective purposes.

- Liners – Extra-strong bladder installation and replacements.

- Advanced Waterproofing and Epoxy Sealant – Spray-on surface waterproofing technology.

Detailed Tank Specification

Due to the growing need for efficient space utilization, square-shaped GRP, HDG, and Stainless Steel panel tanks are among the most sought-after and effective liquid storage solutions. Traditional cylindrical water and chemical tanks waste valuable space, leaving usable areas empty.

Raven American Tanks designs and installs panel tanks that perfectly match your specific space and capacity needs, offering a variety of options.

Sizes & Capacities

- The panels are manufactured in 1m² dimensions – Raven American Tanks can design and assemble tank solutions of virtually any size or capacity suited to the specific application.

- Reach out to our team to discuss specific site requirements or custom sizing requests.

Panels, Materials & Construction Options

- Galvanised Reinforced Polypropylene

- Hot Dipped Galvanise Steel

- Stainless Steel

- Standard powder coated finishes available

Nozzle Types

- 15mm – 400mm Standard – Various attachment types

- For nozzle sizes larger than 400mm, please contact us to discuss your large nozzle fitting needs.

Standard Inclusions

- Galvanised Roofing

- 1 x Manhole

- 1 x External Ladder

- Inlet and Outlet

- Overflow

- Drain

Things to Keep in Mind

- Foundations and groundwork must be prepared and provided before delivery and construction.

- The importance of cleaning and maintenance – Stagnant water stored for months or years can lead to internal corrosion buildup, posing potential hazards.

- Disaster Prevention – Neglecting maintenance can cause corrosion, leading to equipment failure and potentially resulting in flooding, electrical problems, carpet damage, and extensive water damage to buildings. Keep your maintenance logbook current as required by law to ensure the safe operation of your tank.

When will my tank be ready?

Once your final design order is confirmed, Raven American Tanks will generally deliver your tank within 6 weeks of your approval and will start construction as soon as possible.

Our team typically needs between 1 and 4 weeks to assemble the tank, depending on its size, and have it ready for filling.

Delivery times may vary based on your location and project specifics, and your tank could be delivered outside the initially estimated timeframe.

Please contact us if you have any concerns about freight or assembly schedules so we can discuss alternative delivery arrangements.

- NEED A QUOTE?

Get in touch

Contact the Raven American Tanks team to discuss maintenance requirements and pricing structures for our entire panel tanks range today!