Secondary Containment & Bund Liners

- Home

- Secondary Containment & Bund Liners

SECONDARY CONTAINMENT & BUND LINERS

Raven American Tanks provides and professionally installs secondary containment systems and liners for a range of industrial spill bunds. Depending on surrounding commercial activity and the environment, your panel tank may need an overflow solution to handle spills or leaks.

We offer both permanent and temporary secondary panel tank leak-proofing, with custom-designed bund liners to reinforce virtually any sized or shaped liquid catchment.

Also known as berm tank liners, exterior bund liners create a secondary line of defense, safeguarding the tank’s nearby ecosystem and the wider environment.

Enhanced Chemical Spill Containment - Tank Liners America

Industrial panel tanks, GRP panel tanks, and concrete water tanks are utilized for the storage and dispensing of various liquids. While leaks from water reserves might not pose significant environmental threats, hazardous substances such as chemicals can cause serious damage.

Secondary containment liners, typically installed at the base of the tank or within an existing bund system, are crucial for managing potential catastrophic leaks or total tank failures.

Unexpected leaks can easily contaminate drainage systems, waterways, rivers, lakes, or other environmental areas.

Constructed from polymeric tank liner materials, secondary containment is essential when storing hazardous substances, particularly in aging tanks of variable quality.

Bund Liner Features

- Permanent or temporary lining options.

- Versatile, all-terrain adhesion.

- Optional additional drainage or collection system.

- Highly versatile application range – resistant to fuel, oil, and UV.

- Custom-manufactured to accommodate virtually any scale or specific dimensions.

- Top-tier contamination prevention – compliant with EPA and American Standards.

Secondary Containment: Common Uses

Raven American Tanks provides highly versatile bund liner and secondary containment tank liner solutions. Our products and installations adhere to all American safety and WHS standards, ensuring your site is protected against accidental contamination and potential personal injury.

We have supplied and installed secondary liners across various American industries, including:

- Mining and Heavy Industries

- Waste Management Facilities

- Hospitality and Food Processing

- Military Bases

- Washdown Bays and Workshops

- Manufacturing

- Oil, Gas and Fuel Industries

Custom-Engineered for High Performance

Dams, concrete water tank bunds, and other containment systems should be professionally fitted with high-quality, abrasion-resistant, and UV-resistant protection.

Often used in farming, agriculture, or other remote locations, bund liners can accommodate your galvanized tank structure and effectively contain fuels, oils, and chemicals.

Our custom-made bund liners replace the need for double-walled tanks in mine sites and avoid the construction of additional, costly containment support structures in rural, inaccessible areas.

Application-engineered design

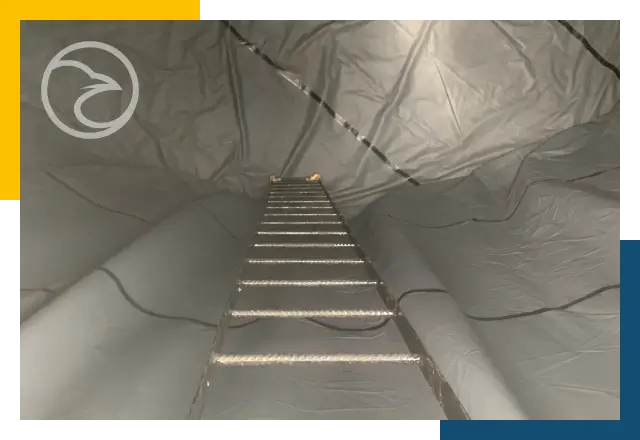

We’ll ensure your secondary containment liners are precisely cut to fit your individual tank or bund setup. It’s crucial for liners to align perfectly with the system to prevent leaks or seepage caused by misalignment.

Geomembrane liner material forms the extra-strong, long-lasting film designed to attach seamlessly to bund systems.

Our bund and containment liners are highly adaptable, providing innovative permanent or temporary support for a variety of industrial panel tank and concrete tank applications.

All liners are precision-cut to accommodate pipework, fittings, electrical obstructions, and other obstacles commonly encountered during secondary containment barrier installations.

Contact us through our inquiry form or speak with a secondary containment and bund liner expert today!

- NEED A QUOTE?

Get in touch

Reach out to the Raven American Tanks team today to discuss maintenance needs and pricing for our entire panel tank lineup!